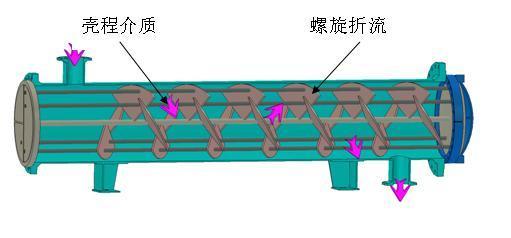

While it is a spiral channel for baffles of the spiral baffles plate efficient heat exchangers. When shell-side medium is filled in from the shell entrance, it flows oblique forward along the spiral channel. That change the traditional horizontal way into the vertical helical mode .

1 The pressure loss of helical heat exchangers is very low. The work fluid flows helically in the shell side and hence avoids the serious pressure loss caused by transverse fluid flow.

2 At the same pressure drop, heat transfer coefficients of shell-sidw with helical baffles could be significantly higher than those with segmental baffles because of the higher average flow velocities across the tubes.

3 The helically fluid flow in the shell-side causes velocity gratitude in the radial section and forms radial turbulence, which will make the viscous sub-layer in the tube surface thinner, contributing to high heat transfer coefficients.

4 There are no dead spaces compared to those with segmental baffles. It offers low fouling characteristics and steady heat transfer resistance to ensure the heat exchangers in high-efficient running status.

5 The constraints of spiral baffles plate to the tubes are stronger than segmental baffles. The effective bundle protection against flow-induced vibrations, prolong the heat exchanger units’ running-length.

6 In the case of shell side condensation , helical baffles can lead the condensation liquid flow, mitigate the liquid covering on the downside tube bundles. It will result in high heat transfer efficiency.

7 It can be used with a variety of efficient heat exchange tube on the principle of internal reinforcement heat transfer which can be reinforced at both inside and outside of the tube in the same time. Therefore, it is further enhanced for overall heat transfer effectiveness of the heat exchanger.

8 The configuration of the spiral baffles plate heat exchangers is almost the same as that of the general segmental heat exchangers .The only difference lies in the type of shell side baffle plates. The apparent shape of tubes and the size of the conjunction between the tubes and shell body are consistent with one another. The replacement of segmental baffles core with spiral baffles core can be proceeding during the maintainence to improve heat transfer performance.